Unleashing Excellence in Electrical Plastic Molding: The DeepMould.net Advantage for Metal Fabricators

In the intricate world of manufacturing, the integration of high-quality plastic components with metal frameworks has become a cornerstone for innovative, durable, and reliable products. At DeepMould.net, a leading metal fabricator, specializing in Electrical Plastic Molding, we have established ourselves as industry pioneers dedicated to delivering unparalleled precision and quality in plastic injection molding processes.

Understanding Electrical Plastic Molding: A Critical Component in Modern Fabrication

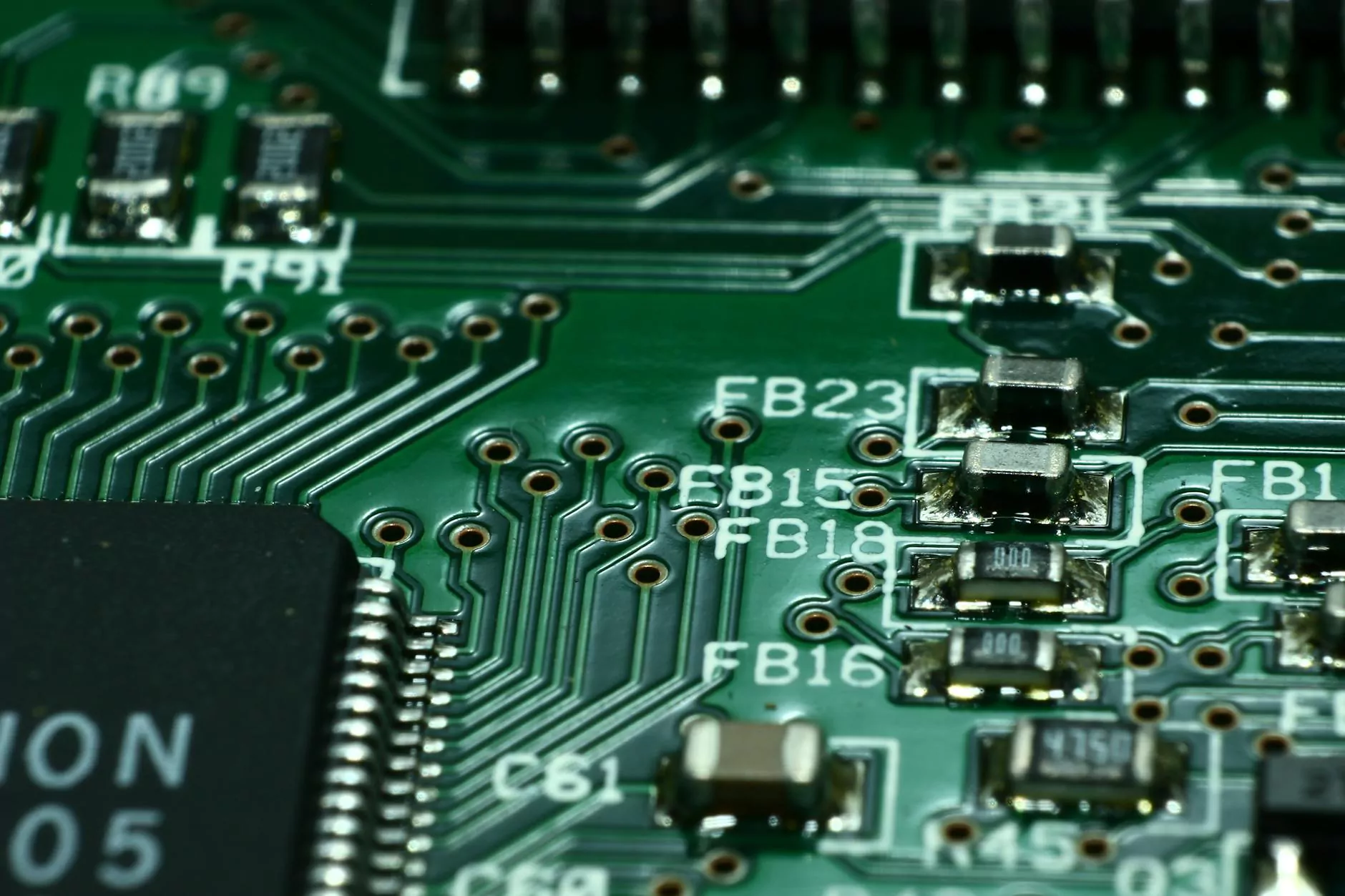

Electrical plastic molding involves the manufacturing of complex plastic components that are essential in electrical assemblies, consumer electronics, automotive interfaces, and industrial machinery. This process combines advanced molding techniques with innovative material formulations to produce parts that meet stringent electrical, mechanical, and safety standards.

What makes Electrical Plastic Molding indispensable? It is primarily the ability to create intricate, high-precision parts rapidly and cost-effectively, ensuring consistency across large production runs. These components often serve as insulative housing, connectors, switches, or enclosures, demanding superior quality, durability, and resistance to environmental factors.

Why DeepMould.net Is the Preferred Choice for Electrical Plastic Molding in Metal Fabrication

At DeepMould.net, our integration of Electrical Plastic Molding into our portfolio complements our expertise in metal fabrications. This synergy enables us to offer comprehensive solutions for complex assemblies that require seamless interaction between plastic and metal components.

1. Cutting-Edge Technology and Equipment

Our facility is outfitted with state-of-the-art injection molding machines capable of handling high-volume production with tight tolerances. From micro-molding to multi-cavity molds, we leverage advanced technology to ensure that every plastic part meets exact specifications.

2. Superior Material Selection

We work with only the highest quality, electrically suitable plastics such as polyamide (nylon), ABS, polycarbonate, and PBT. These materials are chosen for their excellent electrical insulation properties, resistance to heat, chemicals, and mechanical stress — crucial attributes for electrical components.

3. Precision Mold Design and Manufacturing

Our dedicated team of mold designers employs 3D CAD modeling and simulation tools to develop robust molds that produce flawless parts. We ensure repeatability, durability, and optimal cycle times, reducing production costs while maintaining high standards.

4. Quality Assurance and Certification

Quality is at the core of everything we do. Our electrical plastic molded parts undergo rigorous inspection, including coordinate measuring (CMM), electrical testing, and fitment verification. We adhere to international standards such as ISO 9001, ensuring every product is tested and certified for safety and performance.

The Process of Electrical Plastic Molding at DeepMould.net

Understanding our comprehensive process helps appreciate why we are a leader in this industry:

- Design Consultation and Prototype Development: We collaborate with clients to design the plastic parts, ensuring compatibility with metal components and adherence to electrical standards.

- Material Selection: We recommend the best plastics based on application requirements, environmental factors, and electrical performance.

- Prototype Production: Rapid prototyping enables testing, validation, and adjustments before full-scale manufacturing.

- Mold Manufacturing: Leveraging advanced CNC machining, EDM, and polishing to produce high-precision molds.

- Mass Production: Utilizing automated injection molding lines to manufacture consistent, high-quality parts at scale.

- Inspection and Testing: Conducting electrical insulation tests, dimensional analysis, and performance validation.

- Packaging and Delivery: Safe handling and timely delivery ensure client satisfaction and seamless integration into assembly lines.

Applications of Electrical Plastic Molding in Modern Industries

The flexibility and reliability of Electrical Plastic Molding make it invaluable across a spectrum of industries:

- Electrical and Electronics: Connectors, insulative housings, switch components, circuit board enclosures.

- Automotive: Dashboard controls, wiring harness components, sensor housings.

- Medical Devices: Insulating casings, sterilizable connectors, precision switches.

- Industrial Equipment: Control panels, safety covers, and terminal blocks.

- Consumer Products: Smart home devices, audio equipment enclosures, gaming consoles.

Advantages of Choosing DeepMould.net for Your Electrical Plastic Molding Needs

Partnering with us offers numerous benefits:

- Unmatched Expertise: Decades of experience in metal fabrication and Electrical Plastic Molding ensure top-tier solutions tailored to your project.

- Customization: We provide bespoke services, from design optimization to rapid prototyping, ensuring your specific needs are met.

- Cost Efficiency: Through process optimization and high-volume capabilities, we reduce your overall manufacturing costs.

- Quick Turnaround: Our efficient workflows and advanced machinery enable faster delivery timelines without compromising quality.

- Global Standards Compliance: We meet international quality and safety standards, providing peace of mind for clients worldwide.

- End-to-End Support: From concept to delivery, our team offers continuous support, ensuring your project’s success.

The Future of Electrical Plastic Molding and Metal Fabrication

Innovation drives our industry forward. At DeepMould.net, we are embracing emerging technologies such as Industry 4.0, smart manufacturing, and AI-driven design. These advancements enable us to offer even more precise, efficient, and sustainable electrical plastic molding solutions.

Moreover, sustainability is integrated into our processes, focusing on recyclable materials, energy-efficient machinery, and waste reduction initiatives, aligning with global commitments to environmental responsibility.

Conclusion: Elevate Your Manufacturing with DeepMould.net’s Electrical Plastic Molding Expertise

In today’s competitive landscape, relying on a trusted partner like DeepMould.net can make the difference between mediocrity and excellence. Our specialized Electrical Plastic Molding services, backed by advanced technology, rigorous quality standards, and a customer-centric approach, position us as the premier metal fabricator to transform your ideas into high-performance, reliable products.

Maximize your manufacturing potential by choosing DeepMould.net — where innovation, quality, and precision meet.